On 25th March, the School of Mechanical Engineering (SME), HUST received a grant of devices from Viet Nam Petrochemistry Trading and Investment Joint Stock Company (VNPETRO) for training and practices in Transportation Engineering.

At the signing ceremony, Assoc. Prof Truong Hoanh Son, Dean of the School of Mechanical Engineering expressed his desire to develop cooperation between SME and VNPETRO. This grant was regarded as an impetus for SME to improve training quality, combine training with practice, experiential learning and increase/create students’ success.

Assoc. Prof. Truong Hoanh Son, Dean of SME, presented at the meeting

The Dean of SME believes that this grant would make a significant contribution to the success of curricula, encourage students to pursue endeavors, and advance the training quality of experts in Transportation Engineering in general and Automotive Engineering in particular.

Mr. Pham Anh Tuan, CEO of VNPETRO emphasized that sustainable development was a superior purpose that VNPETRO has been pursuing. This purpose has fostered VNPETRO to initiate a cooperation with SME, HUST.

Mr. Tuan believed that SME, HUST is the top university in mechanical engineering, trained many generations of leaders in the top entrepreneurs in various industries including Viet Nam automobile industry.

Mr. Pham Anh Tuan, CEO of VNPETRO presented at the meeting

HUST will cooperate with VNPETRO in the Project: ‘Supporting SME students to approach environmental-friendly technologies”. The Project is matching to VNPETRO’s objective: to be friendly to the environment, and diminish harmful effects on health, soil, water, and air qualities.

VNPETRO Company has supported equipment in auto repair and maintenance with technologies that are environmentally friendly, diminishing harmful effects on health, soil, water, and air qualities:

EAO - HUST

Newer articles

Older articles

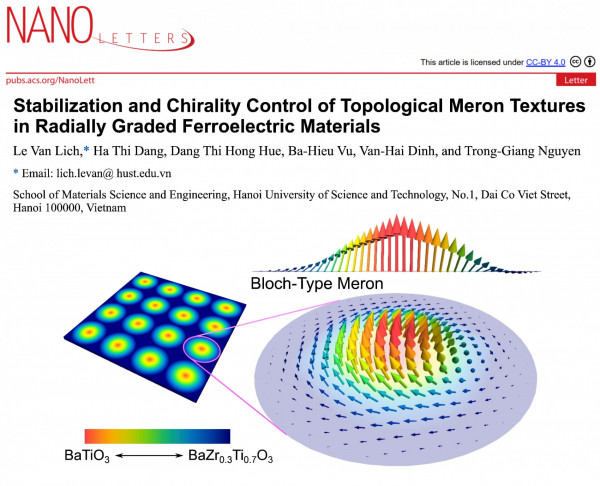

HUST Scientist Publish Ferroelectric Materials Breakthrough...

HUST Scientist Publish Ferroelectric Materials Breakthrough...

Nearly 3,000 HUST Students Graduate in May 2025...

Nearly 3,000 HUST Students Graduate in May 2025...

HUST and TU Dortmund Conduct Joint Scientific Research

HUST and TU Dortmund Conduct Joint Scientific Research

New Vice President Joins HUST Board of Presidency

New Vice President Joins HUST Board of Presidency

HUST Advances AI Research and Applications in Cybersecurity

HUST Advances AI Research and Applications in Cybersecurity

High Demand for HUST Talent at Job Fair 2025

High Demand for HUST Talent at Job Fair 2025

Chemical Engineering Students Can Graduate with KU Leuven...

Chemical Engineering Students Can Graduate with KU Leuven...

HUST Pilots OMO Model to Enhance Digital Education

HUST Pilots OMO Model to Enhance Digital Education

U.S. Ambassador Calls HUSTers the Future of STEM

U.S. Ambassador Calls HUSTers the Future of STEM

AUN-QA Experts Assessed Engineering Programs at HUST

AUN-QA Experts Assessed Engineering Programs at HUST